理工学部、建築・環境学部教養学会主催ミニ講演会 第62回理科系学生のための公開英語講演会

English Lecture Meetings for Science-Major Students

Miniaturization of Electric Devices:

The Latest Report from Germany

電子デバイスの小型化:ドイツよりの最新研究報告

講師:理工学部、表面工学コース

小岩 一郎 先生

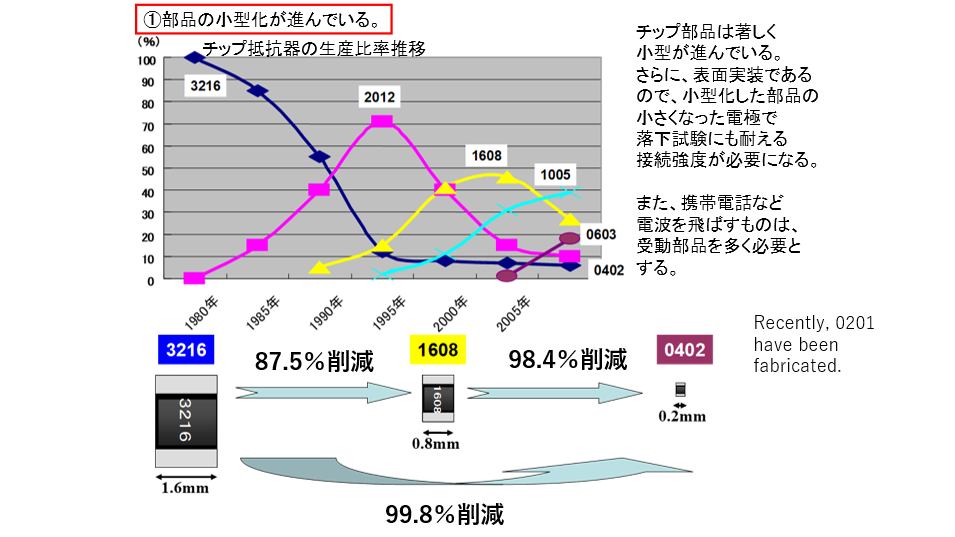

It is obvious that miniaturization of electronic devices has extremely improved the quality of our life, as exemplified by the fact that it has enabled everyday use of our cell phones or PCs as small as the ones we now use. In fact, there is no single area of our life which this development has not brought a lot of benefit to: implantable-sized medical apparatuses have tremendously improved patients’ quality of life; wearable fitness trackers have helped athletes improve their record time; and the list could go on and on and is impossible to exhaust.

Miniaturization of electric devices has proceeded with amazing speed and held to the present day as predicted by Moore’s law, a prediction or prescription for future progress of miniaturization made back in 1965 by Gordon Moore (1929-2023), a co-founder of Intel Corporation.

On December 4th, 2023, the 62nd session of the English Lecture Meeting for Science Major Students was held under the sponsorship of the Academic Society of Faculty of Liberal Arts, inviting Doctor Ichiro Koiwa of the Department of Science and Technology as a lecturer. It was the second opportunity to have Dr. Koiwa as a speaker for this event.

Dr. Koiwa, a leading scholar and an expert in the field of Electronics Packaging Technologyエレクトロニクス実装工学 and Thin Film Engineering薄膜工学, has been engaged in the research into high density mounting of a semiconductor chip for such devices as mobile phones and development of new materials suitable for thin film engineering.

In the first half of this lecture, Dr. Koiwa talked briefly in English about the history of the miniaturization of electronic devices, recent development of research in the field of chemistry, Moore’s law, and further challenges for miniaturization. Dr. Koiwa has shown how miniaturization of electric devices has been accomplished with much success and as much failure since 1960s, also showing his prospect for the development of miniaturization hereafter, i.e., whether Moore’ law will remain valid in the future or not.

In the second portion, the lecturer reported in Japanese on topics such as the differences he found in life and research among the institutes in Germany, Silicon Valley and Japan. Dr. Koiwa also mentioned various interesting episodes experienced during his recent stay as a research fellow in Germany.

In the subsequent Q and A period, the following questions and answers were exchanged between the audience and the lecturer:

Q Having read the text, I now understand that it is extremely difficult to advance the miniaturization of semiconductors, thereby following Moore’s law continuously from now on. Does that hold true in any type of current semiconductor industry?

半導体の小型化を進め、ムーアの法則に今後も従うのは非常に難しい事が分かりました。それは現在のどの種類の半導体産業にも当てはまりますか。

A Yes, it does. In the current semiconductor industry, though the electronic devices are miniaturized, their inner structures have become more and more complicated; naturally, the cost for manufacturing those devices has become incredibly expensive in proportion with their complexity. As a result, only three or four companies in the world can now manufacture the latest type of device in this market.

Q It is said in the text, “As a result of following Moore’s law for the past 40 years, leading-edge companies now manufacture devices with feature sizes below 180 nm.” I would be happy if you could tell us what the most impressive one was among all the devices of such a minute size that you have ever seen, and in what respect that device was so great?

テキストに「過去40年の間にムーアの法則にしたがった結果として、最先端企業は今や180ナノメートル以下の形状サイズの装置を製造している。」とありますが、先生が今まで見た中で最も感動したこのようなサイズの機器は何でしょうか、またどのような点が素晴らしいのかも聞かせて頂けると嬉しいです。

A Now I am very interested in a novel technology called “Chiplet.” Untiltoday, one chip used to have numbers of distinct functions. In this latest technology, distinct functional IC units are separately placed in their blocks; still, those separate computational units connect with each other on a single monolithic circuit board. We can expect to resolve the cost problem that I mentioned in my answer to the first question with this technology.